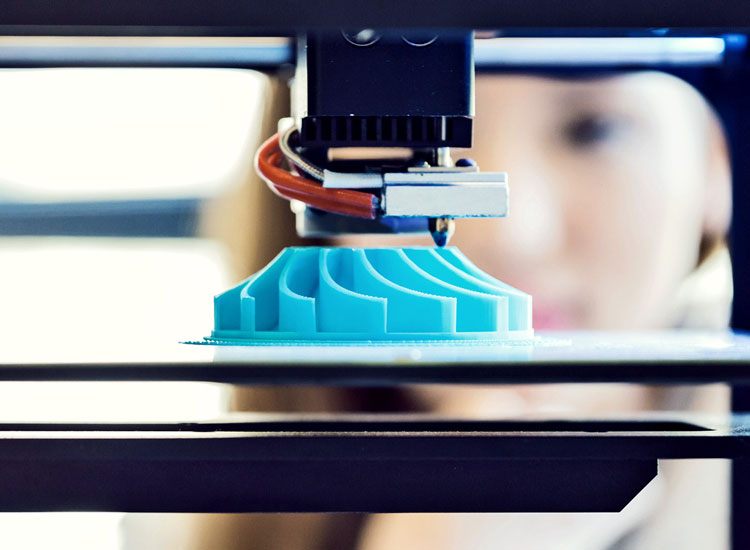

Nitrogen Generators for 3D Printing

When oxygen is allowed to permeate the 3D printing process, it can cause oxidation and discoloration, which negatively impacts the finished product. However, with the help of nitrogen from an on-site generator, you can eliminate oxygen and improve the overall quality of your product.

How 3D Printing with Nitrogen Improves the Additive Manufacturing Process

Additive manufacturing involves using a laser to lay down layers of plastic, metal, or composite material in order to create a final product. Oxygen can disrupt this process by causing sheets of oxidation to form. However, when nitrogen is added, it displaces the oxygen and creates a completely inert environment that doesn’t interact with the laser or the material that is being used to make the product.

Benefits of Nitrogen Generators for 3D Printing

Nitrogen generators work by taking in atmospheric air, extracting the nitrogen, and releasing all of the oxygen and other gases. This creates a constant supply of pure nitrogen. Generators provide many benefits to the 3D printing process, including:

- Improved Efficiency – Because generators provide consistent, on-site access to nitrogen, you won’t risk running out of your supply. This improves the overall productivity of your business.

- Lower Nitrogen Costs – Nitrogen generators can save you a significant amount of money when compared to standard nitrogen cylinder delivery. This is because generators create your nitrogen on-site, so you don’t have to pay for transportation or recurring rental fees. And unlike cylinders, nitrogen generators do not leak.

- High-Quality End Products – Because nitrogen displaces oxygen and prevents oxidation from occurring, generators can help ensure a high-quality final product.

3D Printing Nitrogen Generators from On Site Gas

On Site Gas offers nitrogen generators for 3D printing. Manufacturers, laboratories, and other industries that create custom products or prototypes with 3D printers can choose from our selection of turn-key or custom-built products, including:

- PSA Nitrogen Generators – If your goal is to provide your 3D printing processes with a consistent flow of nitrogen while lowering your business’ overall carbon footprint, choose from our line of PSA nitrogen generators. These machines are known for their high-quality nitrogen production, quick ROI, and stable year-round costs.

- Membrane Nitrogen Generators – These turn-key systems are low maintenance and can produce nitrogen purity levels of up to 99.5 percent.

- Custom-Built Nitrogen Generators – If you need a nitrogen system that can accommodate unique needs and specifications, consider one of our custom-built nitrogen generators. We will work with you to design a machine that’s perfect for your business.

- Nitrogen Filling Stations – Businesses that frequently use nitrogen off-site may benefit from our filling stations. These systems can be used to fill nitrogen cylinders – and can even be connected to existing generators.

Improve Your End Product with Nitrogen Generators for 3D Printing

On Site Gas has been designing and manufacturing reliable, high-quality generators since 1987. We pride ourselves in providing our customers with efficient, cost-effective systems that can be customized to fit their business’s unique needs. To learn more about 3D printing with nitrogen generators, or to place an order, contact us today.