Nitrogen Generation for Bright Annealing

Because of the potential for oxidation, bright annealing requires high purity nitrogen when the oven temperature is over 1,500° F, however, the greatest volume of N2 gas is needed during the cooling phase. As the temperature drops, the percentage of O2 in the product stream can go up without any oxidation to the product. To this end, our proprietary purity selector switch/purity exchange valve is a perfect fit for annealing. The nitrogen generator system can be tuned down to deliver very high purity N2 gas as well. As the temperature goes down during the cooling process, the PFX valve can be adjusted to a different nitrogen purity. Regardless of how it’s done, the annealing process is perfectly mated with a PSA nitrogen generator.

Recommended Nitrogen Systems for Bright Annealing

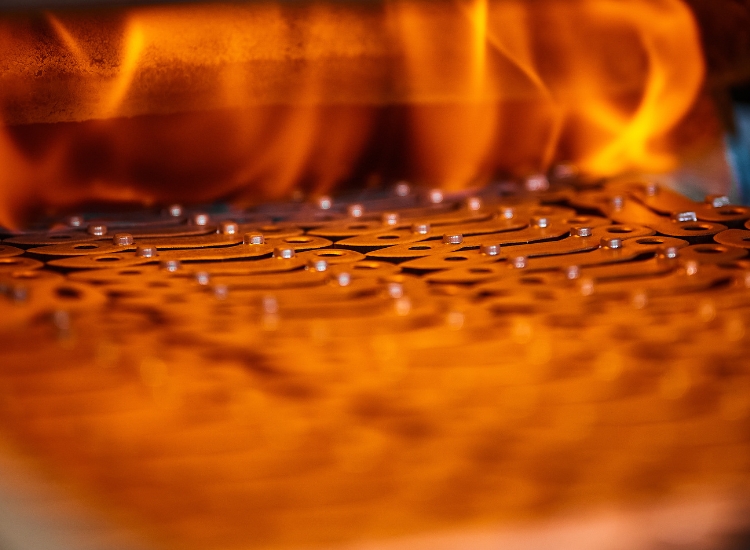

Bright annealing is an essential process used to improve the grain structure of metal and other materials by softening it, enhancing its flexibility, and making it less brittle. The annealing process improves the strength of the metal and makes it easier to machine. Bright annealing can be applied to aluminum, chrome, cobalt, copper, Inconel, low carbon steel, stainless steel, titanium, and high-temperature alloys.

There are three phases in the annealing process as the metal is heated at high temperatures. The phases are recovery, recrystallization, and grain growth. The controlled temperatures and atmosphere result in a brighter surface and a more tinny oxide coating. If the annealing process is not well controlled, then unwanted cracks, pitting, stains, and corrosion can appear on the metal. For optimum results, the air must be oxygen-free. Nitrogen with a purity of 99.99% and higher is used in the bright annealing and oven curing processes.

Nitrogen Systems for Bright Annealing

An annealing furnace heats materials to 1500 degrees Fahrenheit or higher. Oxidation of the finished material is a concern with temperatures this high. That’s why a high level of nitrogen gas is needed during the cooling phase. This results in the quality assurance of a high-performing metal. With the reactive property of oxygen causing material oxidation, nitrogen annealing is the preferred option for creating an inert atmosphere.

With On Site Gas, your bright annealing process is perfectly mated with our PSA nitrogen generator. Plus, our exclusive PFX valve for controlling levels of nitrogen can be customized into each system. To learn more about On Site Gas Systems’ products, contact a member of our team today!