Nitrogen Gas Generation for Selective Soldering

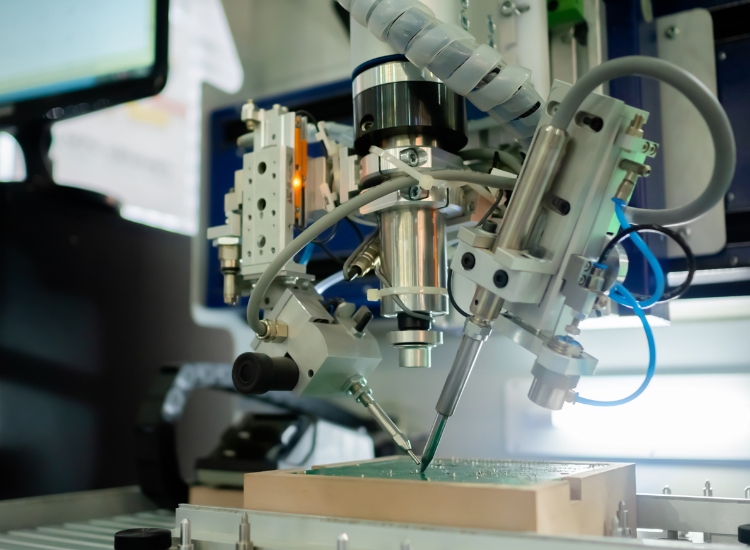

High purity nitrogen gas is used in many solder applications – including selective soldering. The benefits of inert nitrogen gas for selective soldering include reduced dross on solder pots and reduced surface tension, which allows solder to cleanly break away from the solder site. Nitrogen purities typically range from 99.99% to 99.9995%, but consult your OEM owners manual for exact requirements.

Recommended Nitrogen Systems for Selective Soldering

Nitrogen systems play a significant role in the selective soldering process. Any lead in a soldering joint can destroy a solder line and increase production time significantly. A reliable and efficient selective soldering process requires the use of high-purity nitrogen gas. Without a supply of high-purity nitrogen, excess dross can build up around the work area. In a lead-free selective soldering process, nitrogen allows soldering to continue without dross overwhelming the nozzle. A turnkey nitrogen generator system from On Site Gas can easily control the flow of high-purity nitrogen.

A pressure swing absorption (PSA) nitrogen generator provides your operation with a full ready-to-go system designed to ensure your supply of nitrogen is of the purest possible quality. PSA nitrogen generator systems help ensure a steady flow of nitrogen into your work area. PSA generators control your nitrogen supply and keep costs low by compressing air into high-pressure nitrogen and low-pressure oxygen waste. Let On Site Gas help to determine the best nitrogen generator or cylinder delivery system for your operation.