Nitrogen Generation for Curing Facilities

Because of the potential for oxidation, bright annealing requires high purity nitrogen when the oven temperature is over 1,500° F, however, the greatest volume of N2 gas is needed during the cooling phase. As the temperature drops, the percentage of O2 in the product stream can go up without any oxidation to the product. To this end, our proprietary purity selector switch/purity exchange valve is a perfect fit for annealing. The nitrogen generator system can be tuned down to deliver very high purity N2 gas as well. As the temperature goes down during the cooling process, the PFX valve can be adjusted to a different nitrogen purity. Regardless of how it’s done, the annealing process is perfectly mated with a PSA nitrogen generator.

Recommended Nitrogen Systems for Bright Annealing

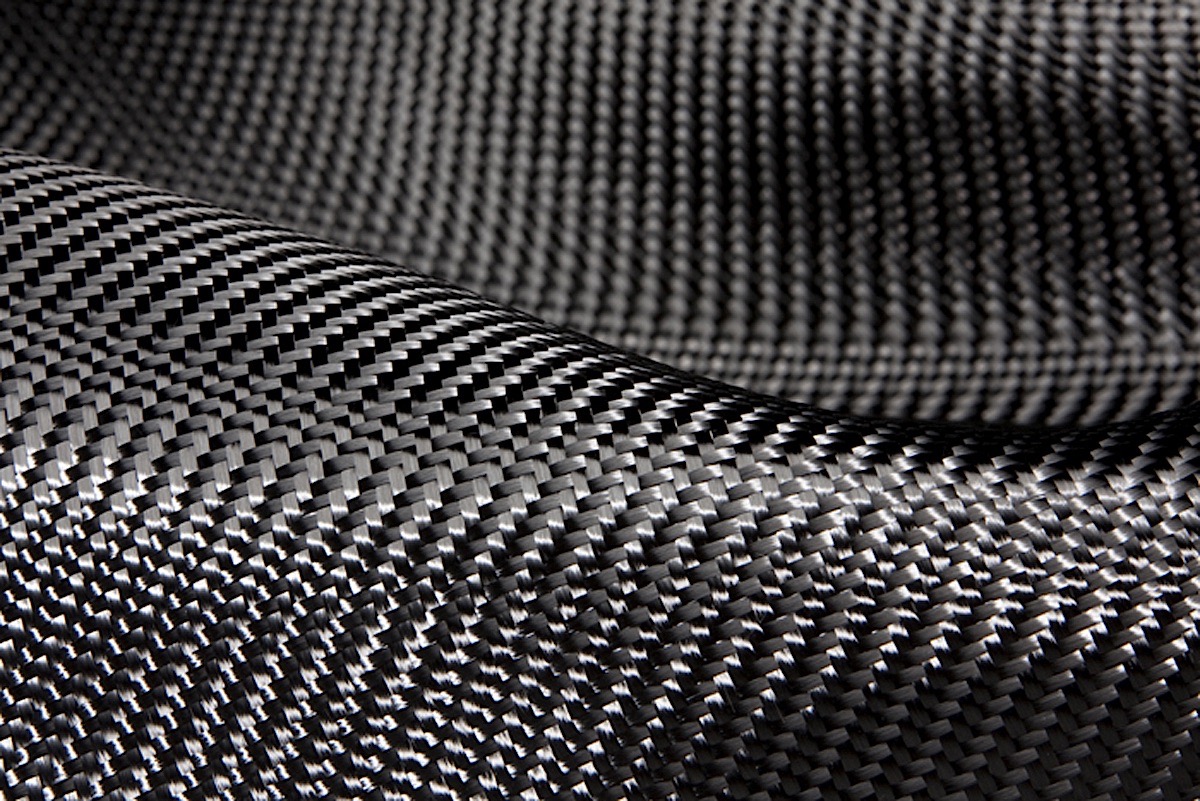

Carbon fiber, a polymer, is also known as graphite fiber. It is a remarkable material that is very strong yet light in weight. Carbon fiber is 5x stronger than steel and 2x as rigid. It is a sought-after material for manufacturing parts such as aircraft wings, components for automobiles, driveshafts, blades for propellers, containers, and tubing. Using carbon fiber parts in an airplane or car contributes to a lighter-weight vehicle, improved fuel efficiencies, and overall strength and durability.

The process for manufacturing carbon fiber is both chemical and mechanical. Long strands of fibers are heated to extremely high temperatures. Autoclaving and other ovens assure the processing of high-quality carbon fiber. The elevated pressures and extremely hot temperatures provide the consistency needed for uniform carbon fiber reinforced polymer (CFRP) materials.

Carbonization occurs during this process, and the fibers are transformed into long, tightly interlocked chains of carbon atoms. There must be no presence of oxygen as it would cause the fibers to burn instead. A nitrogen generation system maintains a constant flow throughout the manufacturing process. This means keeping a dry atmosphere that is oxygen-free at all times. The finished product cures quickly and evenly and is not subject to bubbling.

Nitrogen Generation For Gas, Carbon, & Fiber Curing

Facilities with autoclaves, ovens, and other curing applications are well suited for the best-in-class nitrogen generation systems made by On Site Gas. To learn more about how each nitrogen generator works, contact us today! We will assist you in choosing the nitrogen generator solution that best matches your needs.