How On-Site Nitrogen Generation Works: A Step-by-Step Guide

In many industrial and manufacturing settings, maintaining a reliable supply of nitrogen is essential. An on-site nitrogen generator allows you to produce nitrogen gas right at your facility, eliminating the need for tank and N2 cylinder deliveries. Below, we’ll break down exactly how on-site nitrogen generation works, step by step, and highlight its benefits for your operation.

What Is an On-Site Nitrogen Generator?

An on-site nitrogen generator is a system that separates nitrogen from ambient air and delivers it at a specific purity, pressure, and flow rate. Instead of depending on nitrogen deliveries, these systems generate nitrogen gas on demand using compressed air as the feed source.

The two primary technologies used for on-site nitrogen generation are Pressure Swing Adsorption (PSA) and membrane separation. Both systems deliver consistent nitrogen output, but each functions differently depending on purity requirements, operating costs, and maintenance needs.

Why Choose On-Site Nitrogen Generation?

There are several compelling reasons businesses across industries are switching to on-site nitrogen generation. Once installed, operating costs are significantly lower than recurring cylinder or bulk delivery expenses. Nitrogen is always available on demand, ensuring uninterrupted operations even during supply chain delays. Producing gas on-site also minimizes waste because nitrogen is generated as needed, not stored and discarded. These systems are compact, freeing up valuable floor space, and they’re safer and more environmentally friendly by reducing truck deliveries and emissions. Lastly, modern nitrogen generators feature built-in analyzers that allow you to maintain precise nitrogen purity levels for your applications.

Step-by-Step: How On-Site Nitrogen Generation Works

Step 1: Air Preparation

The process starts with compressed, dry, and clean air. The air passes through filters that remove particulates, oil vapor, and moisture. High-quality feed air ensures longer system life and consistent nitrogen output.

Step 2: Pressure Regulation

The clean air is adjusted to the operating pressure needed for nitrogen separation. Proper pressure control ensures steady flow and optimal purity.

Step 3: Nitrogen Separation

This is the core of the system, where nitrogen is separated from oxygen and other gases using either PSA or membrane technology.

In a Pressure Swing Adsorption (PSA) system, air enters a vessel filled with carbon molecular sieve (CMS). Oxygen molecules are adsorbed while nitrogen passes through as product gas. When the adsorbent becomes saturated, the vessel depressurizes and regenerates while a second vessel takes over. This cycle continues to provide a consistent flow of high-purity nitrogen gas. PSA systems are ideal for industries that require very high nitrogen purity levels.

In a Membrane Separation system, compressed air passes through membrane fibers that selectively allow oxygen, carbon dioxide, and water vapor to pass through more quickly than nitrogen. The nitrogen remains as the primary output, creating a continuous stream of gas suitable for moderate-purity applications..

Step 4: Purity Monitoring

An oxygen analyzer continuously measures nitrogen purity to ensure the gas meets your specified standards. If oxygen levels increase beyond the set limit, the system automatically adjusts flow or timing to maintain consistency.

Step 5: Delivery to Application

The purified nitrogen is delivered directly to process lines, storage tanks, or other end-use points. Because the system operates on-site, nitrogen is always available without the downtime or logistics associated with deliveries.

Step 6: Venting and Regeneration

In PSA systems, oxygen-rich exhaust gases are vented safely to the atmosphere during regeneration. This allows the adsorbent material to be reused in the next cycle. Proper venting design ensures safe and efficient operation.

Step 7: Maintenance and Optimization

Routine maintenance keeps the system performing at peak efficiency. This includes replacing filters, checking for leaks, calibrating sensors, and monitoring performance metrics. With proper care, nitrogen generators can operate efficiently for decades.

PSA vs. Membrane Nitrogen Generators

Both PSA and membrane nitrogen generators have unique strengths depending on your purity needs and application. PSA nitrogen generators can achieve extremely high purity levels—up to 99.999%—making them ideal for industries like electronics, pharmaceuticals, and metal processing. They have more complex components and require a bit more maintenance but deliver the highest performance where precision matters most.

Membrane nitrogen generators, on the other hand, provide purities up to around 99.5% and are simpler, more compact, and energy-efficient. They’re excellent for applications where moderate purity levels are sufficient. With fewer moving parts and straightforward operation, membrane systems are an economical, low-maintenance solution for continuous nitrogen supply.

Real-World Process Overview

Installing an on-site nitrogen generator typically begins with assessing your facility’s nitrogen demand, including desired flow rates, purity levels, and pressure requirements. The generator modules are then installed and connected to your compressed air and power systems. Once operational, sensors are calibrated, and the system begins its separation cycle. Operators can monitor purity and make adjustments as needed, while ongoing maintenance keeps performance optimized for years to come.

How On Site Gas Systems Can Help

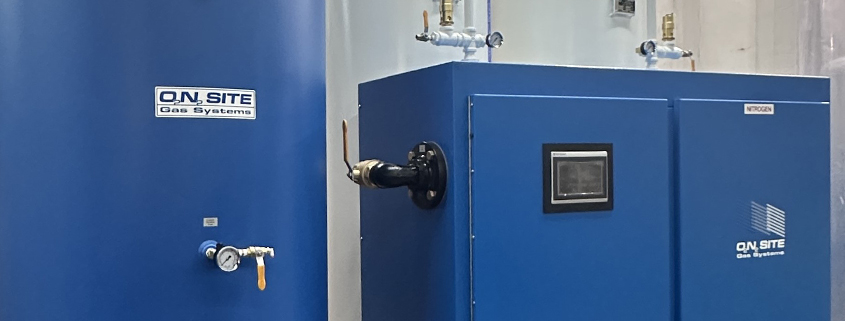

For more than 35 years, On Site Gas Systems has been helping companies around the world gain control over their nitrogen supply with reliable, cost-effective on-site generation solutions. Whether you need a high-purity PSA system or a low-maintenance membrane setup, our engineers can design and build a custom nitrogen generator tailored to your exact specifications.

Contact On Site Gas Systems today to learn how on-site nitrogen generation can improve efficiency, reduce costs, and give your business a steady, independent nitrogen supply.

Leave a Reply

Want to join the discussion?Feel free to contribute!