PRESSURE SWING ADSORPTION TECHNOLOGY

Any business that uses more than one cylinder of nitrogen or oxygen a week should consider an on-site nitrogen or oxygen generator. On Site Gas Systems provides generators to businesses all over the world. These systems are not only more convenient than bulk delivery; they can pay for themselves in less than 12 to 15 months.

Any business that uses more than one cylinder of nitrogen or oxygen a week should consider an on-site nitrogen or oxygen generator. On Site Gas Systems provides generators to businesses all over the world. These systems are not only more convenient than bulk delivery; they can pay for themselves in less than 12 to 15 months.

Custom-Designed, On-Site Oxygen Generators

On Site Gas System’s generators are custom-designed to meet the needs of each client. Generator sizes range from 2 SCFH to 75,000+ SCFH depending on the gas and purity requirement.

A Cost-Effective Solution

This ability to generate nitrogen or oxygen on-site offers businesses considerable savings because it eliminates the need to purchase bulk gas and have it delivered.

Convenience With Pressure Swing Adsorption (PSA) Technology

When one of On Site Gas System’s generators is connected to a business’ air supply (air compressor systems are available), the business has the ability to produce an unlimited supply of nitrogen or oxygen. This is possible through the use of Pressure Swing Adsorption Technology. The use of PSA provides businesses with the convenience of on-demand gas production, thus, essentially eliminating the wait times commonly associated with bulk delivery.

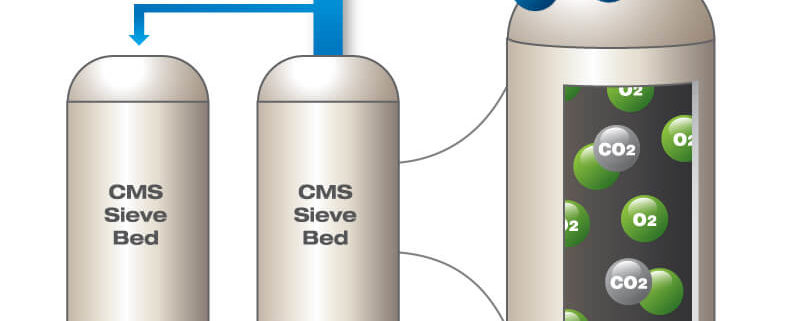

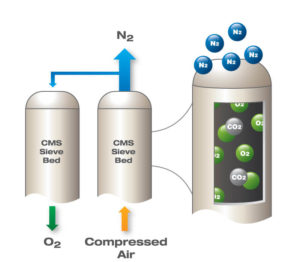

How Pressure Swing Adsorption Works

The air that surrounds us contains roughly 78 percent nitrogen, 21 percent oxygen and 0.9 percent argon (with the remaining balance consisting of other gases): pressure swing adsorption (PSA) technology is designed to separate the nitrogen or oxygen from the rest of the air. This process is possible due to Carbon Molecular Sieve (Nitrogen) or Zeolite (Oxygen). Carbon Molecular Sieve at high pressures, attracts (adsorbs) oxygen, while letting the nitrogen flow to the receiving tank. Zeolite performs the same function with oxygen molecules in our oxygen generators This is the key process behind the best nitrogen and oxygen generators.

The Process of Generation Via PSA

On Site Gas System’s nitrogen and oxygen generator systems consist of two beds: Each bed contains an adsorbing sieve material:

- As the high pressure air enters the first tank, it moves through the sieve, and the oxygen or nitrogen is adsorbed depending on the generator type and output gas required.

- The process gas is then channeled to a buffer or storage tank.

- Directly before the first bed is completely saturated, the feed air is redirected to move through to the second bed, where the same process occurs.

- Once that process is complete, the first oxygen or nitrogen generator bed is vented out to the atmosphere, allowing the waste gas to release from the sieve.

- Completing regeneration of the first bed requires purging it with a small amount of process gas.

- This entire process continues in the oxygen or nitrogen generator until the business’s demand for process gas is met.

The Life of the Carbon Molecular or Zeolite Sieve

Under typical operating conditions (i.e., clean, dry feed air supply), a Carbon Molecular or Zeolite sieve lasts indefinitely.

Productivity of a Pressure Swing Adsorption O2 Generator

The purity of the nitrogen or oxygen gas a business needs affects the productivity of a pressure swing adsorption (PSA). With a fairly small increase in the amount of feed air moving through the sieve, a Pressure Swing Adsorption Generator can produce substantially more process at 95 percent purity than it can at 99.9 percent+.

Reasons Businesses Choose On Site Gas Systems

For nearly 30 years, On Site Gas Systems has been providing businesses all over the world with convenient, cost-effective nitrogen and oxygen generators. ON SITE GAS SYSTEM is FDA, ISO 13485 and ISO 9001 certified, we also comply with ASME, GOST, CRN and PED (among others) to deliver custom-designed oxygen and nitrogen generators to meet even the most demanding engineering specifications.

Because of their durability, our nitrogen and oxygen generators are frequently utilized in the most remote locations and extreme environments. Whether you are in need of portable oxygen generators, a nitrogen filling station or an oxygen generating system, On Site Gas Systems can assist you in creating a gas system that meets your business’s specific needs. Contact us today to learn more.