Can I Have Multiple Purity Levels on a Nitrogen Generator?

The Earth’s atmosphere contains approximately 80 percent nitrogen. Industries ranging from electronics to tire companies use nitrogen on a daily basis; for this reason, many industries create their own nitrogen on site with their own nitrogen generating systems. An on-site nitrogen generator is designed to pull nitrogen out of the atmosphere to provide companies with an unlimited supply of nitrogen so that nitrogen delivery is no longer needed.

Categorizing Nitrogen Grades and Purity Levels

While certain grades of nitrogen are common there is no standardization of nitrogen grades across industries or within a single industry in and of itself, which means the nitrogen manufacturer names the grades and categorizes them accordingly. For this reason, two products with identical purity specifications may be listed under different grade categories, but it is possible for two products with an equivalent grade to have purity specifications that don’t match. Selecting a nitrogen generating system should be based not only on its grade, but also on its purity specifications.

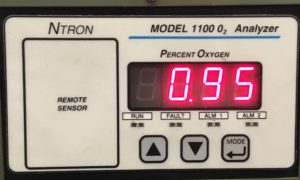

All of On Site Gas’ Nitrogen Generators Have Gas Analyzers

All nitrogen systems available at On Site Gas include gas analyzers: These analyzers ensure precise and current measurement of nitrogen that is being produced. Purity levels are measured in either parts per million (PPM) or percentages. The measurement utilized depends on the setup and requirements of the system being used.

Nitrogen Purity Grades

High-Purity Nitrogen

High-purity nitrogen grades consist of greater than 99.998 percent nitrogen. High purity nitrogen contains less than 20 PPM or less of oxygen and total hydrocarbons. Nitrogen also contains other impurities, including carbon dioxide, water and carbon monoxide. High-purity grades of nitrogen contain no more than, 1.0 PPM of carbon monoxide or 1.0 PMM of carbon dioxide.

Low-Purity Nitrogen

Low-purity nitrogen grades consist of 90 to 99.998 percent nitrogen. Contaminate percentages within these nitrogen grades vary substantially. On Site Gas Systems have lab tested many different purity levels so that we can help determine which purity best suites your particular contaminant requirements.

On Site Gas Offers Multiple Purity Levels on a Single Nitrogen Generator Systemnitrogen

Sometimes, a company needs multiple purity levels. Purchasing or renting a nitrogen generator system for each purity is not only expensive, but inefficient as well. On Site Gas offers nitrogen generator systems that have the ability to provide companies with multiple levels of purity.

Controlling Purities via On Site Gas’ Purity Exchange Valve (PFX)

On Site Gas provides companies the ability to generate three purities with just one system. This is possible via On Site’s purity exchange valve, as switching between purity levels is simple via the nitrogen generator’s touch screen control panel.

Reasons On Site Gas Generation is Superior to Liquid and Cylinder Gas

- No concerns gas prices will increase

- No waste, as is common with liquid installations

- No need to move high pressure cylinders; thus, improving worksite safety

- Lowest cost per m3

- No contracts

- No rental, or delivery fees

At On Site Gas Systems, our technicians have the knowledge, skill and experience to help you choose which system will provide the nitrogen purity levels and grade you need. Whether you need a PSA nitrogen generator or a membrane nitrogen generator with multiple purity levels, or just one purity level, On Site Gas has the innovative, reliable and economical nitrogen generating system to meet your needs. Contact us today to learn more.

Any business that uses more than one cylinder of nitrogen or oxygen a week should consider an

Any business that uses more than one cylinder of nitrogen or oxygen a week should consider an  For almost 30 years, On Site Gas Systems has been providing industries with standard oxygen generating systems, as well as custom designed

For almost 30 years, On Site Gas Systems has been providing industries with standard oxygen generating systems, as well as custom designed

On Site Gas Systems has been serving companies worldwide for almost 30 years and is a world leader in the manufacturing of on-site oxygen generators. At On Site Gas Systems, we create custom designed oxygen generating systems for our clients. Once the system is complete, On Site Gas Systems delivers the custom designed O2 generating system to the client’s physical location.

On Site Gas Systems has been serving companies worldwide for almost 30 years and is a world leader in the manufacturing of on-site oxygen generators. At On Site Gas Systems, we create custom designed oxygen generating systems for our clients. Once the system is complete, On Site Gas Systems delivers the custom designed O2 generating system to the client’s physical location. Our investment in continuous innovation ensures that we can provide our clients with the highest quality

Our investment in continuous innovation ensures that we can provide our clients with the highest quality  Various industries, hospitals, and businesses may feel like they have no other option than to get cryogenic gas delivered in bulk to meet their nitrogen and oxygen needs. But this is not the case. On Site Gas makes it possible for these facilities to generate their own nitrogen and oxygen by means of an O2 & N2 Site self-generating system. When compared to cryogenic gas, these systems offer a variety of advantages.

Various industries, hospitals, and businesses may feel like they have no other option than to get cryogenic gas delivered in bulk to meet their nitrogen and oxygen needs. But this is not the case. On Site Gas makes it possible for these facilities to generate their own nitrogen and oxygen by means of an O2 & N2 Site self-generating system. When compared to cryogenic gas, these systems offer a variety of advantages. During the soldering process, engineers in the electronics manufacturing industry use nitrogen gas. Many times, nitrogen gas is ordered from an outside vendor and delivered to the worksite; however, electronics manufacturing companies should consider using an on-site

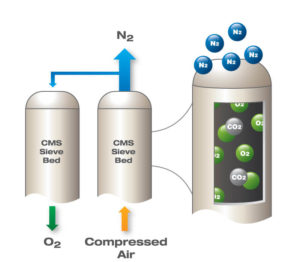

During the soldering process, engineers in the electronics manufacturing industry use nitrogen gas. Many times, nitrogen gas is ordered from an outside vendor and delivered to the worksite; however, electronics manufacturing companies should consider using an on-site  The innovative pressure-swing adsorption (

The innovative pressure-swing adsorption (