Why Choose On-Site Nitrogen Gas Generators over Bottled Nitrogen Gas Cylinders?

A variety of industries, from food packaging to electronics manufacturing, use nitrogen in their daily operations. For many years, the traditional way to obtain this useful gas was to order nitrogen bottles or cylinders that were delivered to your location. Today, however, many companies are making the switch to a more cost-effective, reliable choice: nitrogen generators.

Wondering why nitrogen generators are better than bottled nitrogen gas? Let’s take a closer look.

Nitrogen Bottles vs. Nitrogen Generators: What’s the Difference?

In determining why N2 generators are better than bottled gas, you must first consider a few key facts about how the two systems work. When you buy nitrogen cylinders for your business, you must rely on timely deliveries and ensure you or your employees place orders consistently so that you don’t run out of gas. Plus, because nitrogen cylinders are pressurized, they can pose a variety of safety risks when not handled with care.

You may still be wondering, “why N2 generators vs. cylinders?” The best answer to this question is convenience and availability. When you have your own generator on-site, you eliminate your reliance on nitrogen orders and deliveries. Instead, you can produce the gas you need, whenever you need it. This is because generators draw nitrogen from the surrounding atmospheric air, meaning you’ll always have access to a consistent flow of gas. Nitrogen generators also reduce many of the risks associated with cylinder deliveries, as they don’t include pressurized canisters or liquid nitrogen.

Why Choose On Site Gas Generators for Your Nitrogen Needs

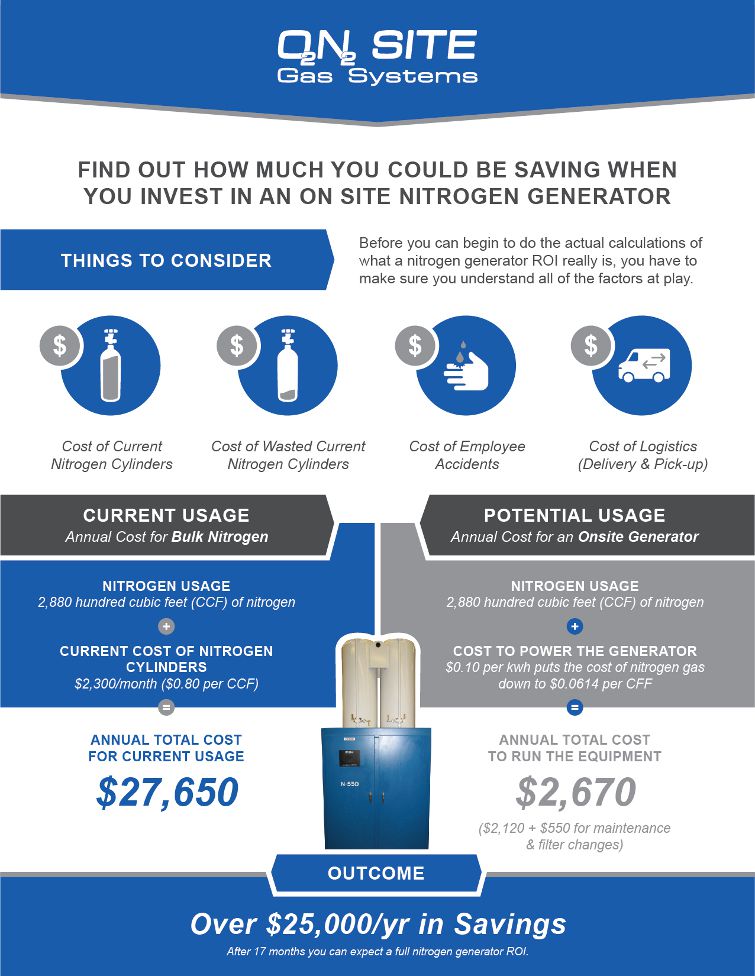

On Site Gas is an industry leader in nitrogen gas generators and supplies. We stand out from our competitors by designing and manufacturing high-output systems that can be customized to fit your unique specifications. Our catalog features a variety of turnkey equipment that provide low operating costs and a high return on investment, including:

- Pressure Swing Adsorption (PSA) Nitrogen Generators

- Nitrogen Membrane Generators

- Nitrogen Membrane Trailer Systems

- Nitrogen Container Systems

- Nitrogen Cylinder Filling Systems

- Custom-Engineered Nitrogen Generation Systems

We even offer refurbished nitrogen generators for a more budget-friendly alternative to a brand-new machine. The best part? All of our systems are designed to produce high-purity nitrogen, with some offering purity levels of up to 99.999 percent! That way, you can ensure your nitrogen gas is suitable for all of your applications.

Enhance Your Operations with a Nitrogen Generator from On Site Gas

Are you tired of relying on nitrogen deliveries to ensure your business can remain operational? Have you run out of gas one too many times, only to wait hours or even days for new cylinders? Not only are these issues frustrating, but they can also result in lost money and wasted time. Luckily, on-site nitrogen generators provide a reliable, cost-effective solution.

If you’re looking to switch to a system that will guarantee you never run out of nitrogen for your industrial applications, contact On Site Gas today. Our knowledgeable team members are happy to answer all of your questions and help you find the right system for your nitrogen needs.